NMRV-E Worm Gear Reducer

Overview of NMRV-E Worm Gear Reducer

- NMRV-E Worm Gear Reducer is made of high quality die casting aluminum alloy housing.

- Worm Gear Reducer possessed great surface area and higher thermal capacity with the heat sink design.

- Due to its low noise and stable running, the reducer can adopts long term work condition in terrible environments.

- Hardened worm with fine grinding has the features of higher efficiency and highoutput torque.

- Good-looking in appearance, durable in service life and small in volume.

Description of NMRV-E Worm Gear Reducer

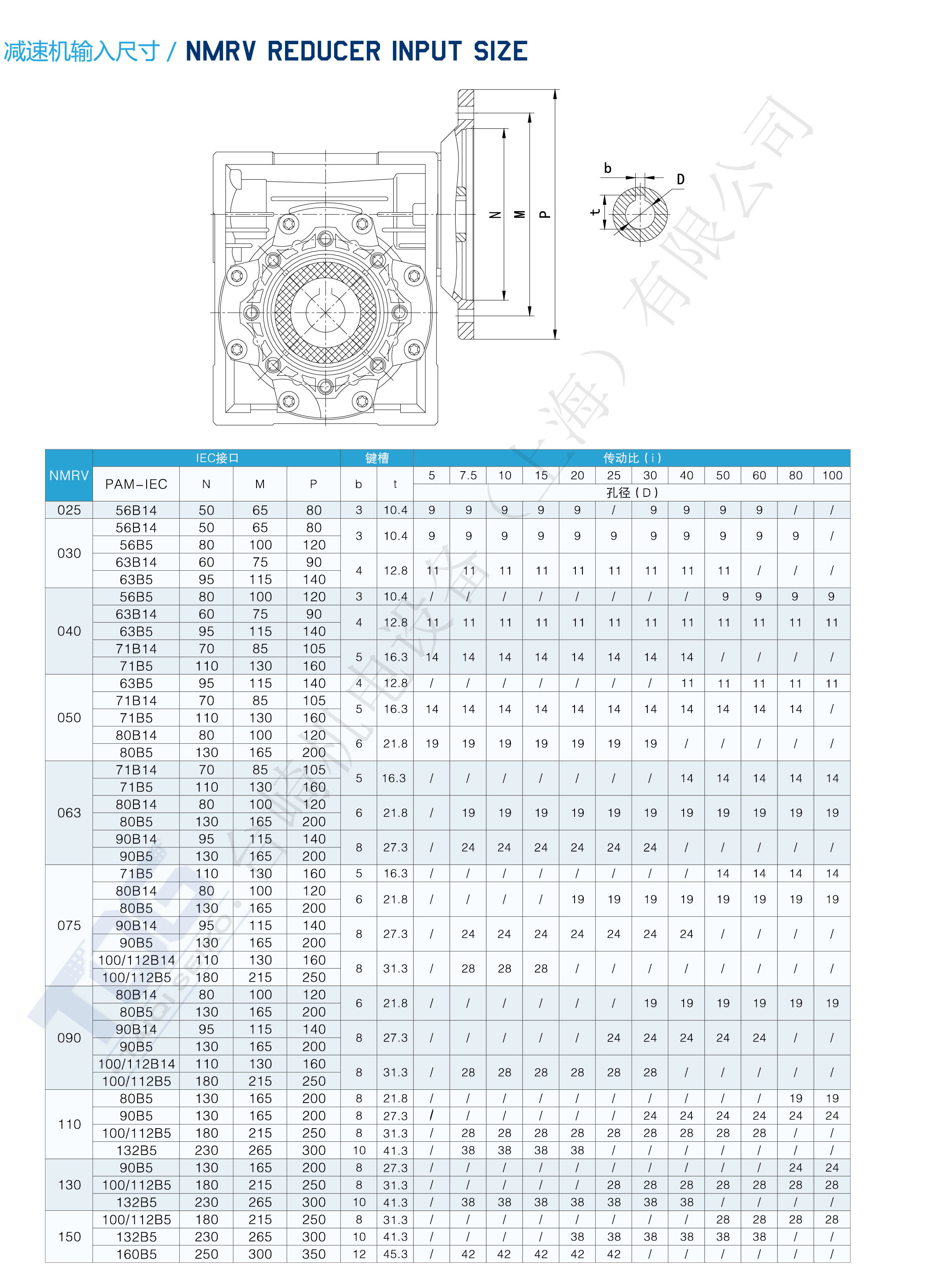

NMRV Series Worm Gear Motor contains worm gear reducer and motor. The worm gear reducer uses low-carbon aluminium alloy cementation processing completely. And the square structure of aluminum gearbox is manufactured according to GB1055588 cylindrical gear parameter standard. NMRV Series Worm Gear Motor adopts many advanced technologies during the process to achieve compact structure.

This TQG NMRV series motor featured with the following characteristics: low noise, good appearance, smooth running, large transmission ratio and high load capacity and it can equipped with many kinds of motors to realize speed adjustment.

Working principle:

The worm reducer is used to reduce the rotating speed and increase torque, and the function is to decrease speed by gears and increase torque.

Maintenance:

- Operating altitude: No more than 4000m.

- Ambient temperature:-25℃~40℃.

- Relative humidity ≤95%(at +25℃).

- Remember tochange the oil after 300-hours operation.

- Please do not mix the mineral oil and synthetic oil.

Please download the complete catalog in the top navigation bar

Please download the complete catalog in the top navigation bar