GH Horizontal Gear Motor

Overview of GH Horizontal Gear Motor

- Good grease lubricity

- High temperature resistance

- Small size

- Light weight

- Low noise

- High cost performance

Descriptions of GH Horizontal Gear Motor

The TQG GH horizontal gear motor has good adaptability which can be equiped with 1-phase motor and 3-phase motor to meet different needs. What’s more, it has two kinds, the ordinary ratioa and the high ratio. According to its output shaft, it could be dividede into two types, the standard type and the shrink frame type. The gear motor is featured with high quality and high-strength material to ensure the superior performance.

Features of GH Horizontal Gear Motor

- The coil adopts imported 100% pure copper coil and the motor will not cause overheating and burnout. 3-layer high-density molecular coating primer layer could block the dust effectively and it has high temperature resistance and the service life expectancyof the GH horizontal gear motoris 10 times longer than the ordinary coatings.

- Gears are machined with imported precision hobbing machines, and chromium-molybdenum alloy steel for charcoal treatment is used to ensure wear resistance of gears. What’s more, the gears meet the national standard anti-corrosion and with precision roller grinding. And the gear is hardened with low noise.

- The shaft rotor is made of high-quality materials, with uniform density distribution, so that the loss is lower and operation is more stable.

- The GH horizontal gear motor adoptsadvanced professional software to design and process and is tested by gear testing equipment to ensure gear precision and noise.

- The motor housings are all made of aluminum alloy shells. The precision grinding of helical gears is tested and assembled. The protection class is IP55 advanced and Class F insulation.

Advantages of GH Horizontal Gear Motor

- Long service life: Adopting tin bronze gear, roller bearing and anti-wear lubricant.

- High reliability: Using insulation high temperature enameled wire, aluminum alloy material and adopting one-piece stamping technology.

- Low in voice: Adopting CNC machining, high-frequency heat treatment and shaft carburizing.

- Compared with the traditional spray painting technology, the electrostatic spray painting plastic technology requires no thinner material, the construction has no pollution to the environment, no harm to the human body, the layer appearance quality is excellent, and the adhesion and mechanical strength are large.

Applications

The TQG GH horizontal gear motor is widely used in packaging machinery, ceramic machinery, woodworking machinery, electronic machinery, construction machinery, glass industry, printing machinery, corrugated machinery, color box machinery, conveyor machinery, food machinery, three-dimensional parking facilities, automatic warehousing, three-dimensional warehouse, chemical, textile, dyeing The entire equipment, environmental protection equipment, mixing equipment, sewage treatment equipment, aluminum equipment and so on.

Precautions

- The motor should be handled carefully during transportation to avoid the damage of the motor body and performance caused by severe impact.

- It must be used according to the specifications of the specification, otherwise it will affect the life of the motor.

- Please use within 6 monthsanddo not store in high temperature, low temperature, high humidity environment. Avoid condensation when using and opening the motor package.

- The motor should be properly operated and no corrosive gas can exist in the storage and operating environment. For example: H2S, SO2, NO2, CL2, etc. In addition, there must be no substances in the storage environment that can emit corrosive gases such as silicon, cyanide, formaldehyde, and phenol. If there are corrosive gases in the mechanical structure or device of the motor, this will cause the motor not to operate.

- Pay attention to the working environment of the motor and avoid dust, otherwise the motor will generate noise and performance will be reduced, thus reducing product reliability.

- The reducer must be installed on a flat and firm base. The foot bolts must be fastened and shockproof.

- When assembling the motor mechanically, the shaft can be coated with butter, which can be quickly assembled

(Note: It is not possible to tap the motor shaft assembly)

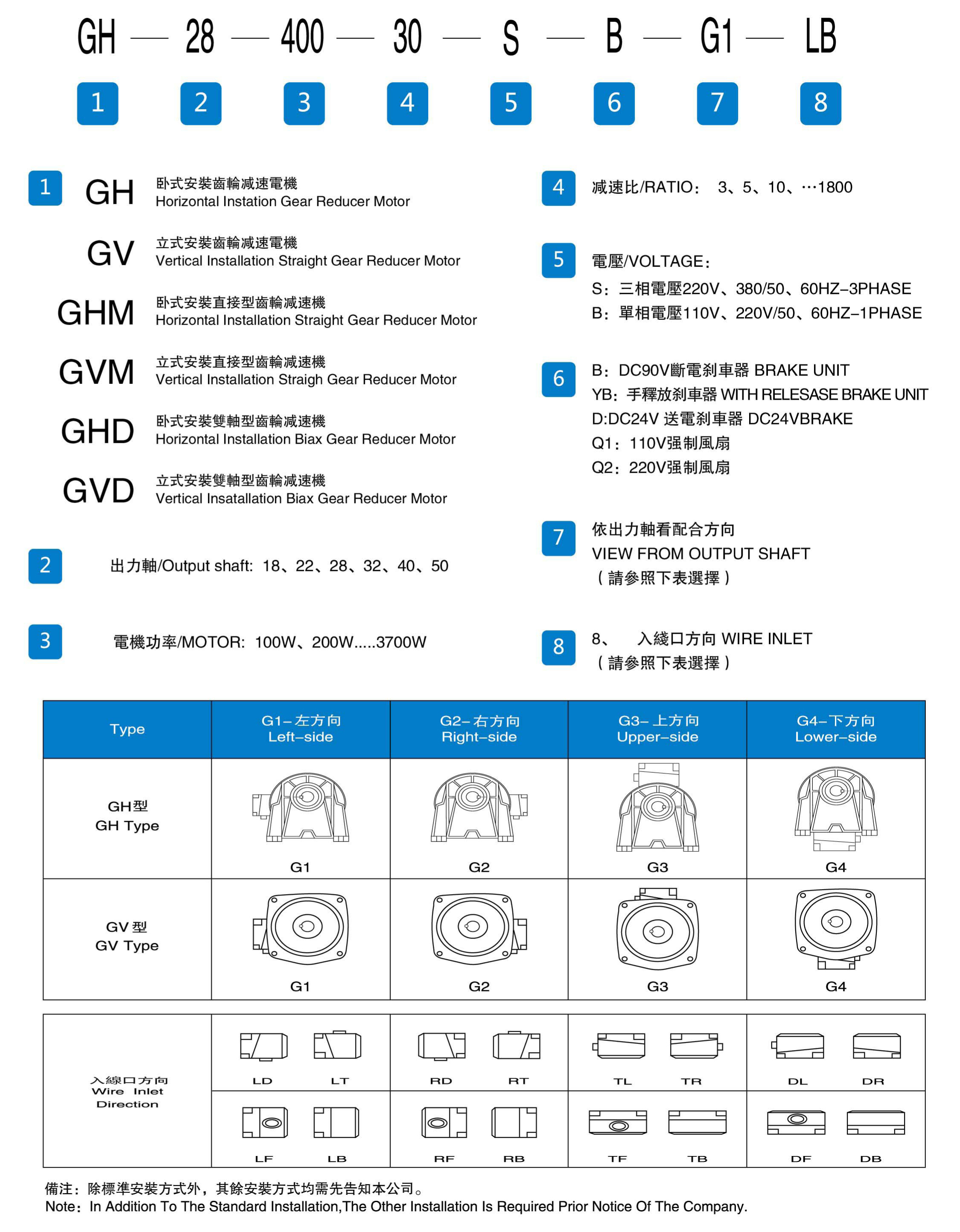

Indication of Model Numbers of GH Horizontal Gear Motor

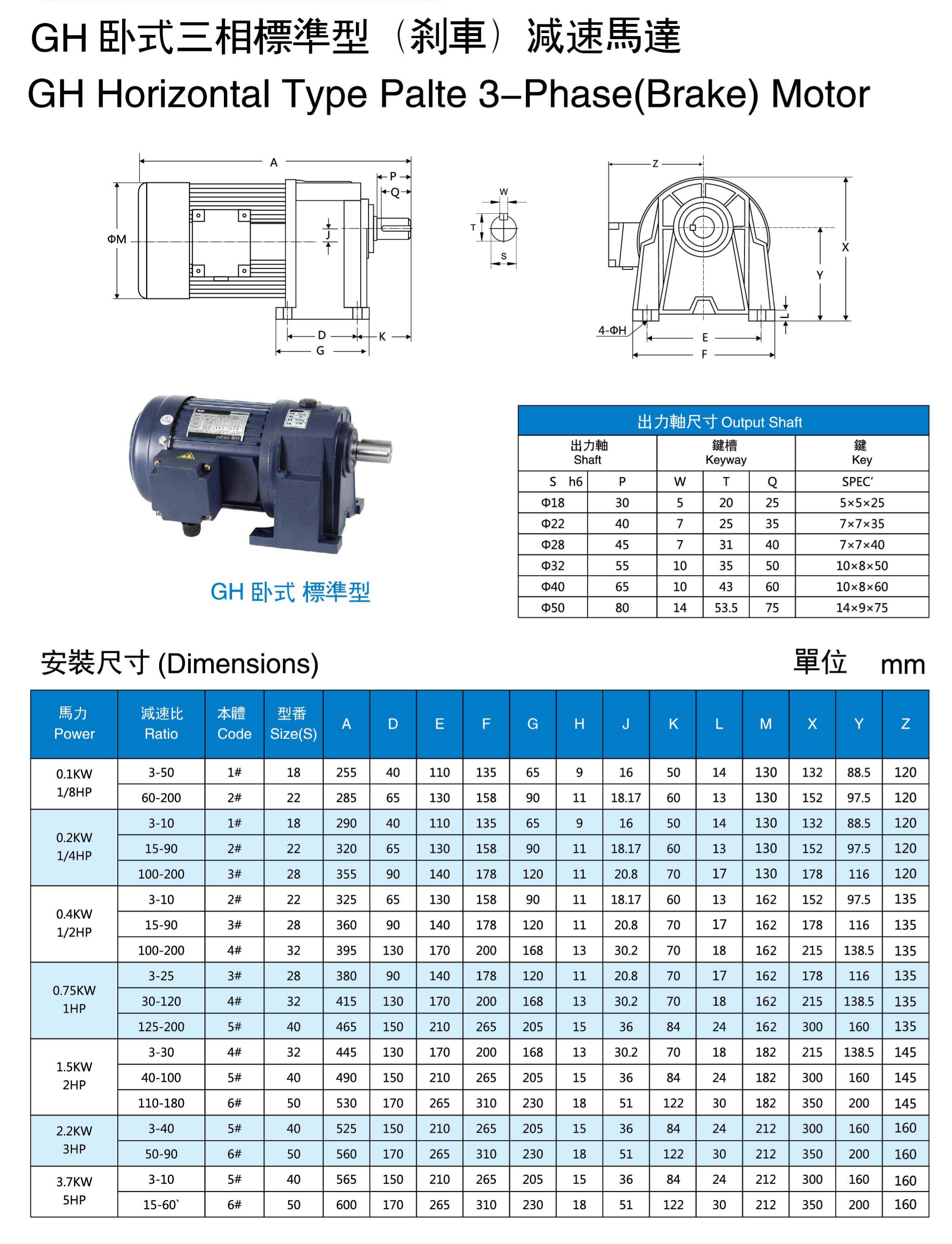

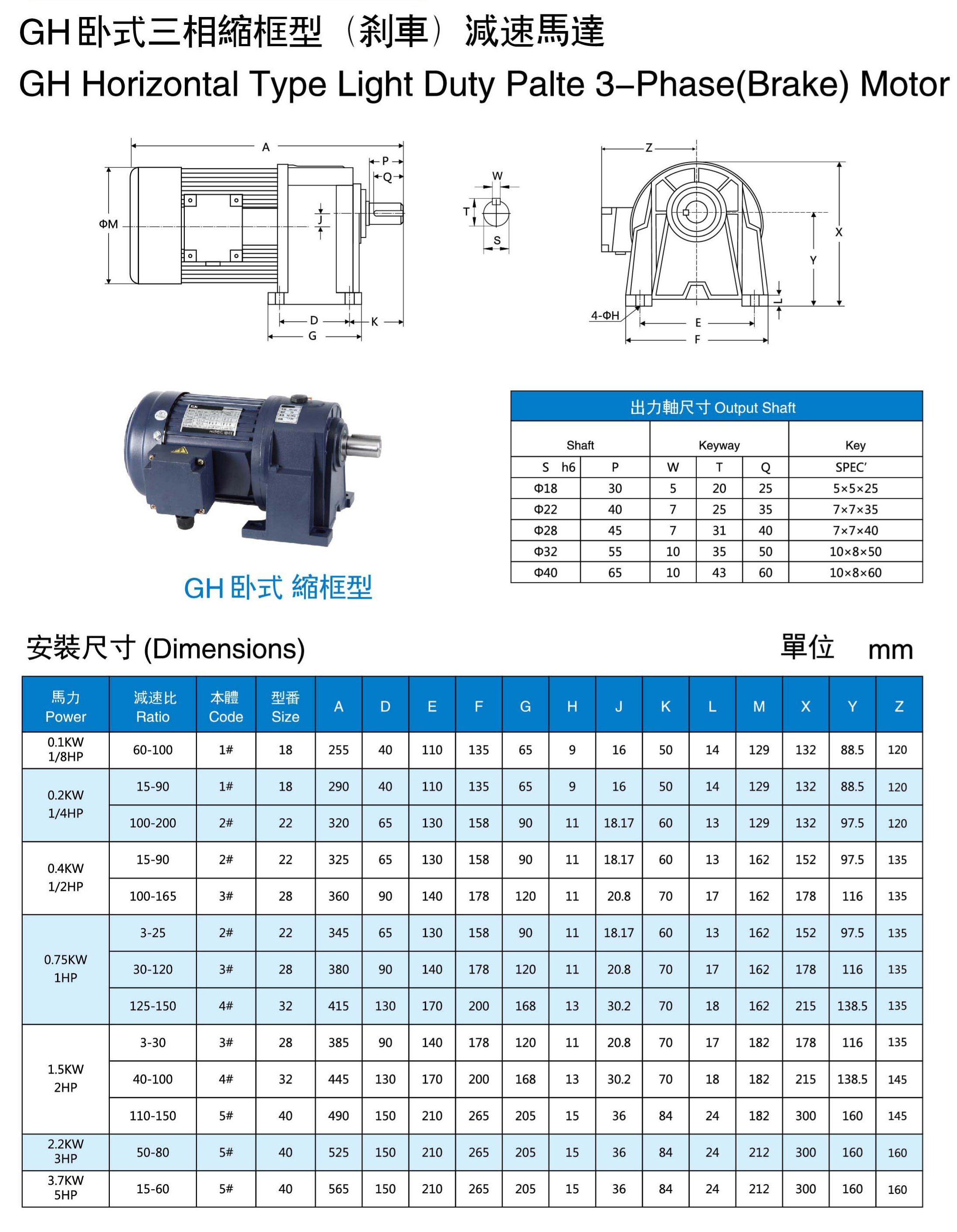

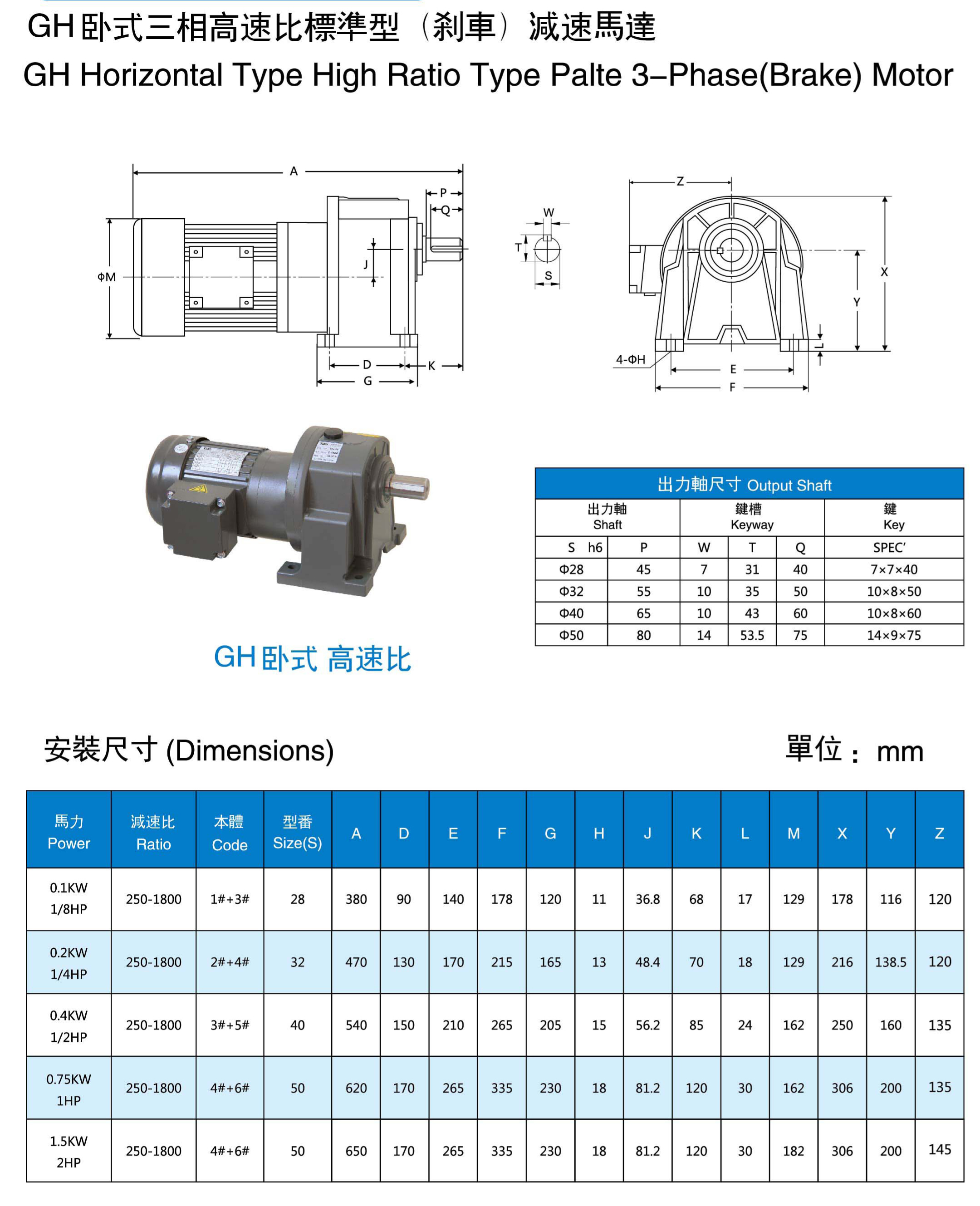

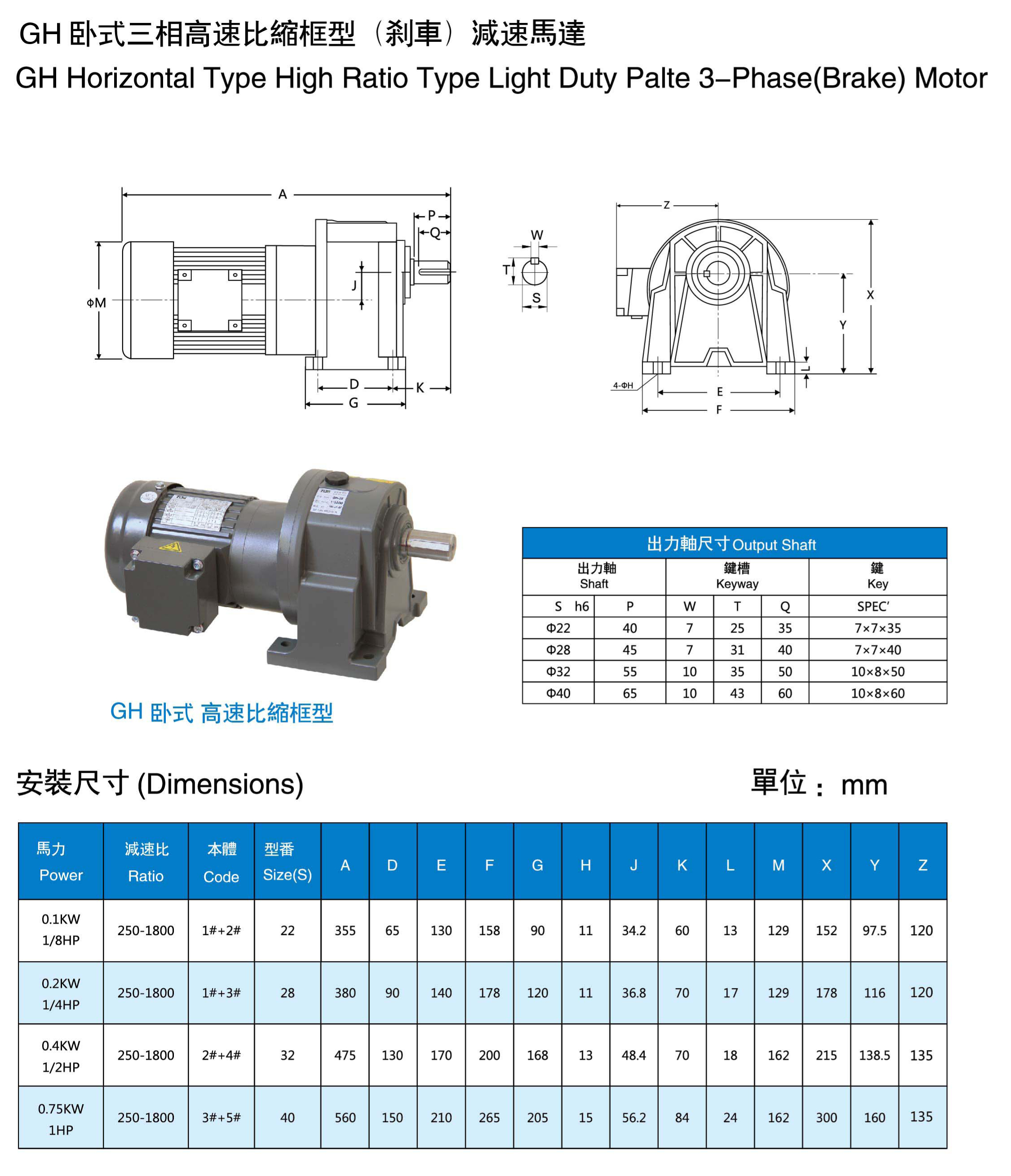

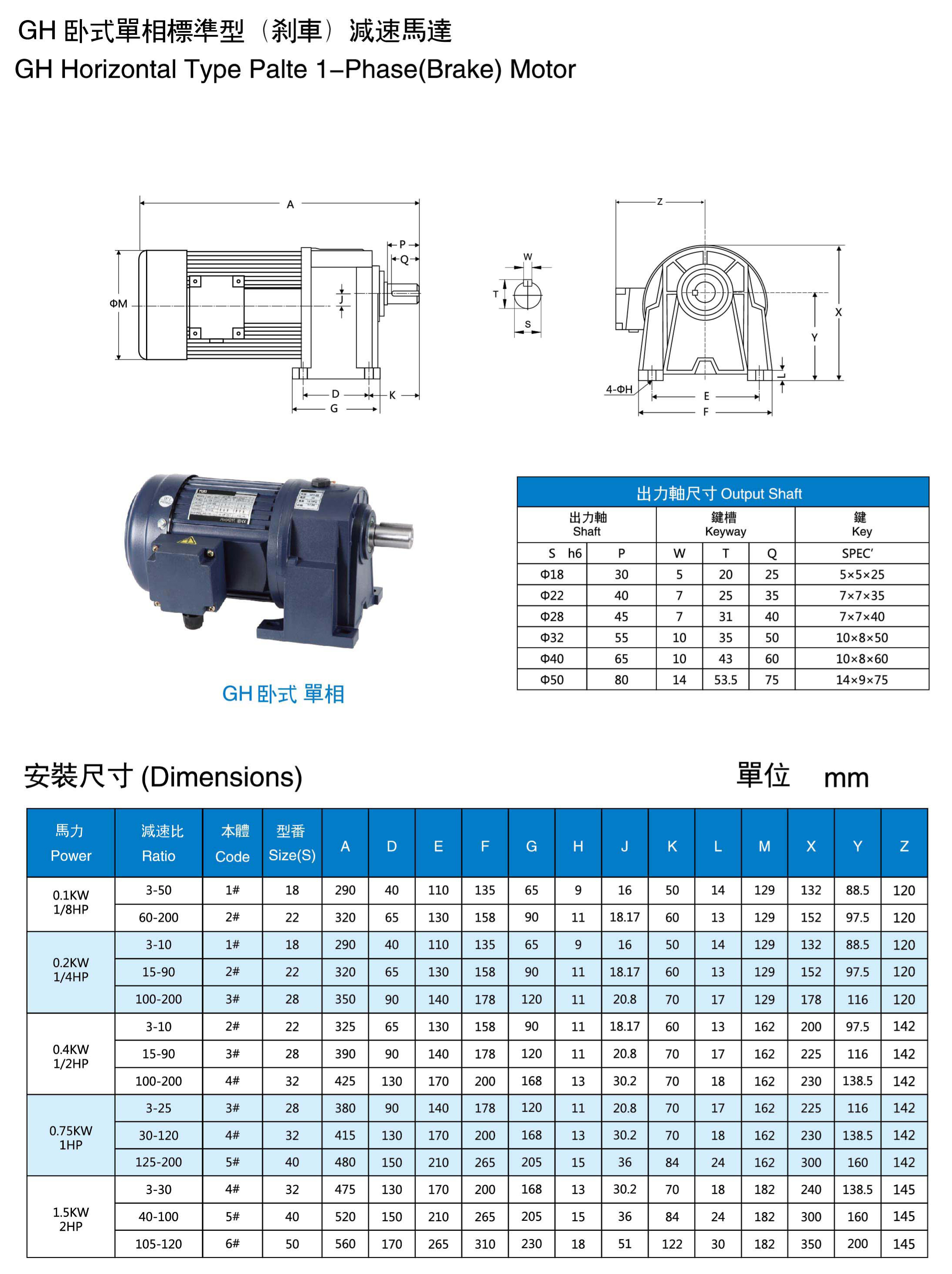

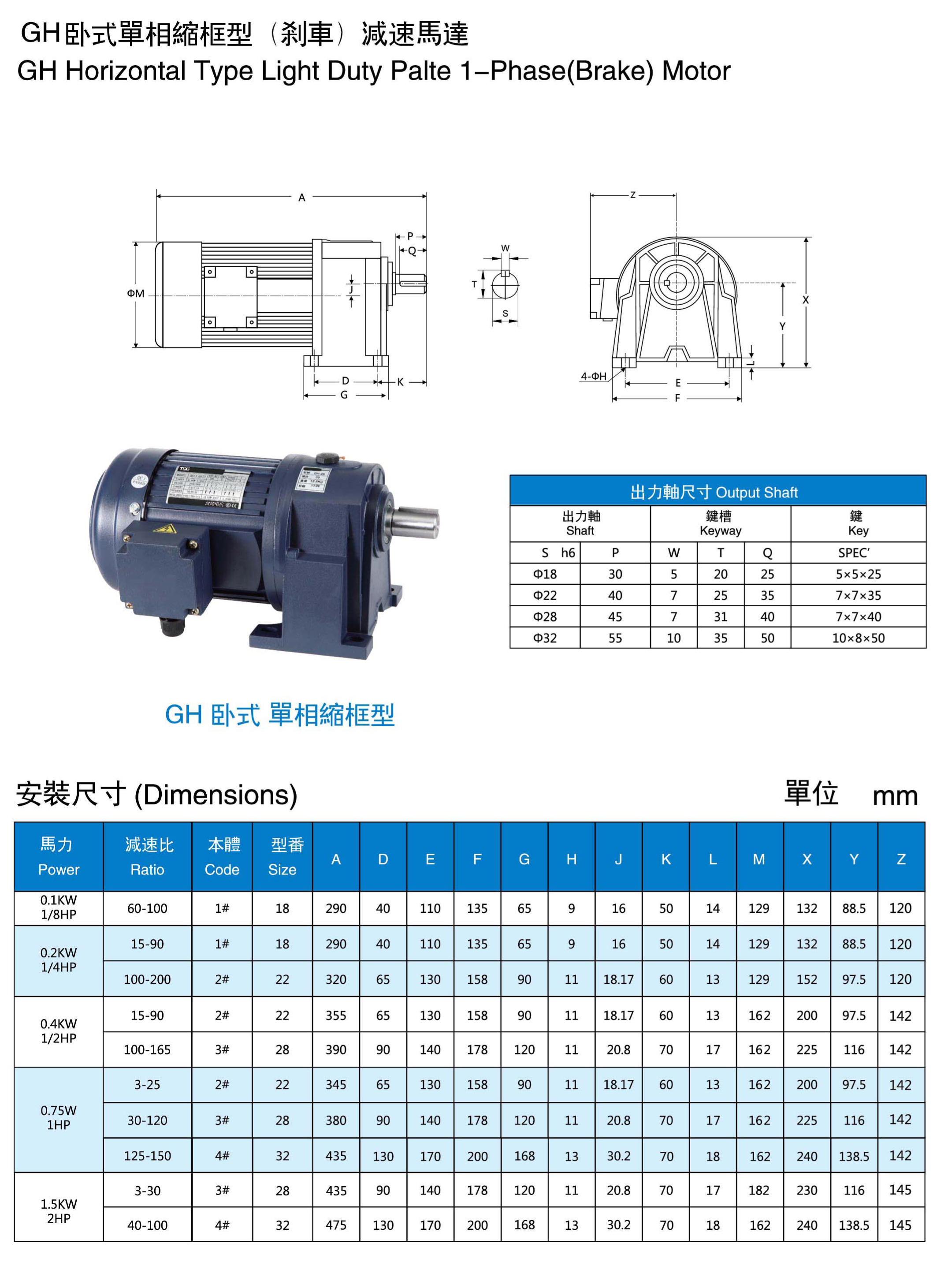

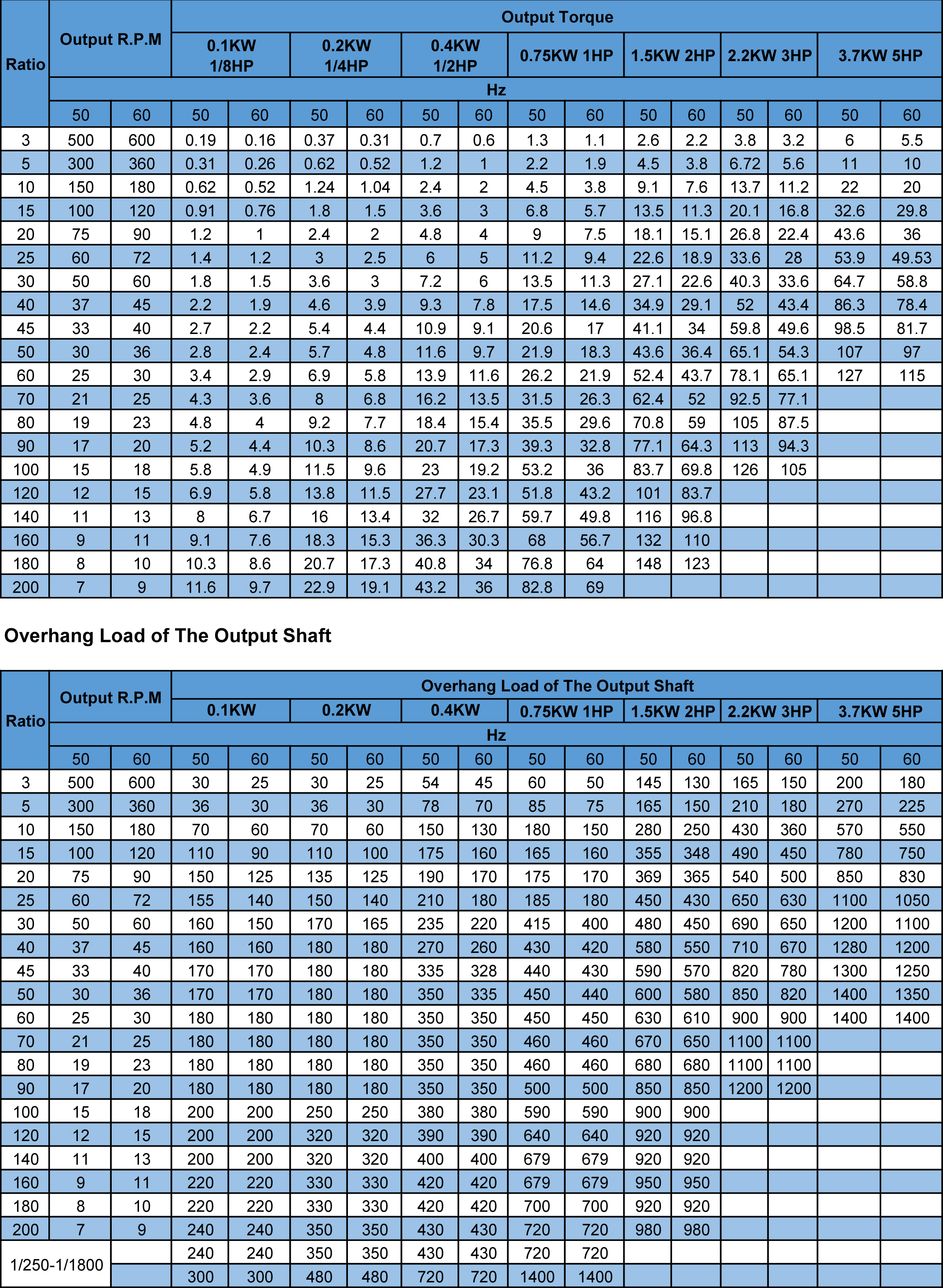

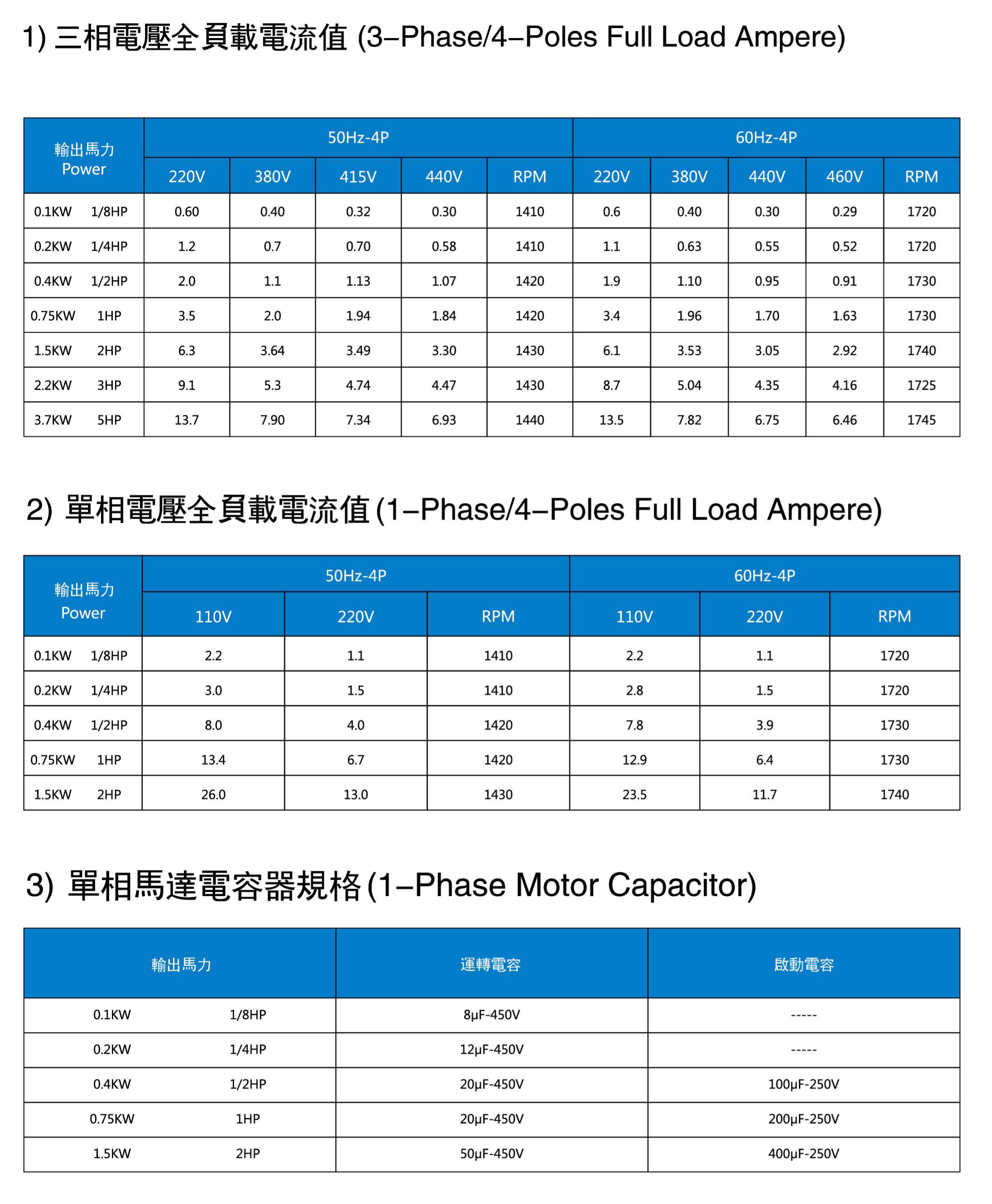

Specification Table of GH Horizontal Gear Motor

Catalogue of GH Horizontal Gear Motor

—Download the complete catalog in the top navigation bar