FHD-C Series Robot Gearbox

Overview of FHD-C Cycloidal Gear Reducer

- Hollow structure which could match with cable

- Large load capacity

- High stiffiness and high rigidity

- High wear resistence

- Double column bracing structure with large torsional stiffiness

- Strong impact resistence which is 500% of the rated torque

- Excellent starting efficiency with low vibration

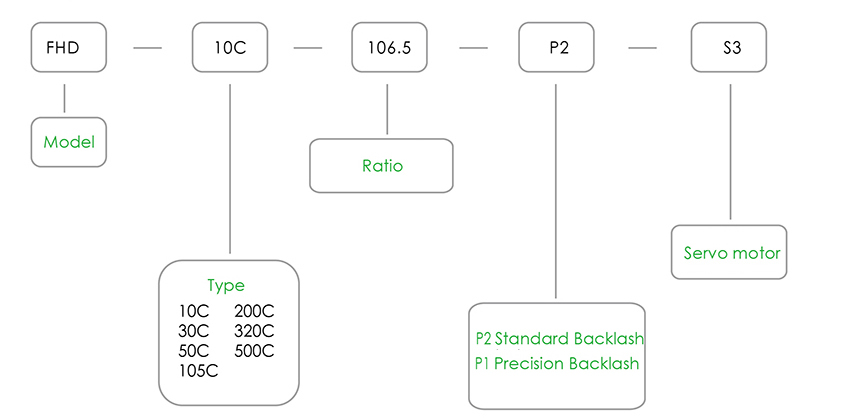

Indication of Model Numbers of FHD-C Series Robot Gearbox

Descriptions of FHD-C Cycloidal Gear Reducer

The TQG FHD-C series cycloidal gear reducer is also called the robotic reducer with high positioning accuracy and low backlash. The FHD-C inline cycloidal gear reducer features a hollow shaft and it could match with the servo motor directly to meet the various industial market requirement. This transmission drive of FHD-C has large number of meshing teeth, low backlash, high transmission precision and high torsional stiffness. In recent years, it has received extensive attention in the field of precision transmission. Besides, trochoid pump which is based on the planetary transmission principle is paid attention because of its smooth operating, small pulsation and low noise druing the meshing process.

Operational principle

The FHD-C series cycloidal gear reducer is a new type transmission drive and is composed of the involute planetary gear reducing mechnism and the cycloid gear planetary reducing mechanism. The core components of the RV reducer are pin gear housing, crank shaft and cycloid wheel. As the input part of the cycloidal gear drive, the involute planetary gear and the crank shaft are joined together. The crank shaft drives the eccentric motion of the cycloid. The crankshaft is rotated clockwise for 1 circle, and the cycloid gear will move 1 teeth along counterclockwise direction.

Features of FHD-C Cycloidal Gear Reducer

- The FHD-C cycloidal gear reducer adopts the load-decentralized technology of the multi teeth meshing which increases the capacity of the impact load.

- The unsmooth torque transmission will be caused due to the wearness and interference of the gear in traditional gear transmission mechnism.

- With the hollow structure design, the FHD-C cycloidal gear reducer could match with the cable through the hollow shaft hole and it could save the installation space.

- The spur gear reducing mechnism and the differential gear reducing mechnism reduce the vibration of the cycloidal gear reducer and slows the revolution speed of RV gears down.

- The FHD-C series cycloidal gear reducer of TQG has amall vibration, high torisonal stiffiness and strong impact resistence which 5 times larger than the rated torque with the using of the double column bracing

- The cycloidal gear reducer adopts the rolling contact structure with rolling bearing which make the FHD-C series reducer possess the excellent starting efficiency, long service, small wearness and low backlash.

Applications

The Taiqi Seiko FHD-C cycloidal gear reducer is widely used in machinery, mining, metallurgy, chemical industry, textile industry and national defense industry and other industries.

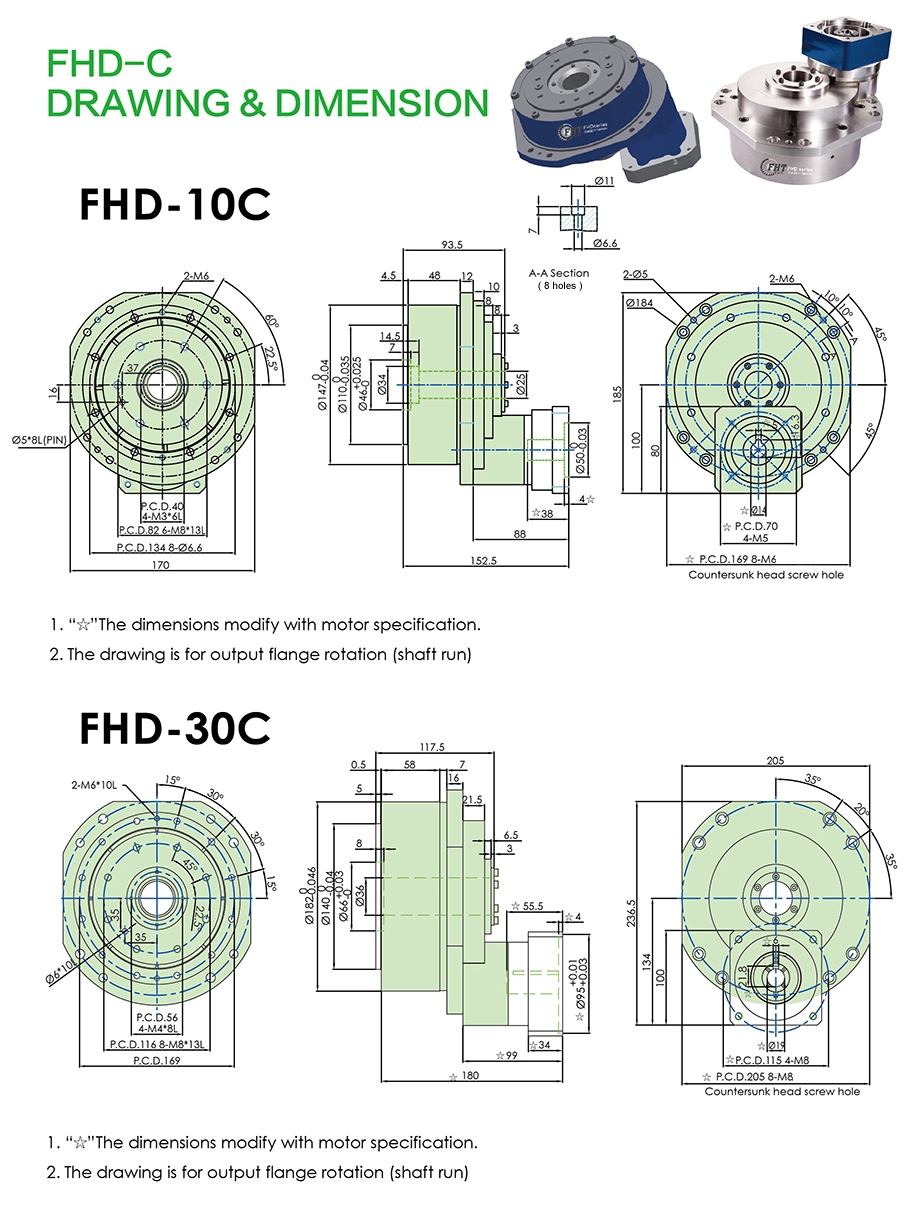

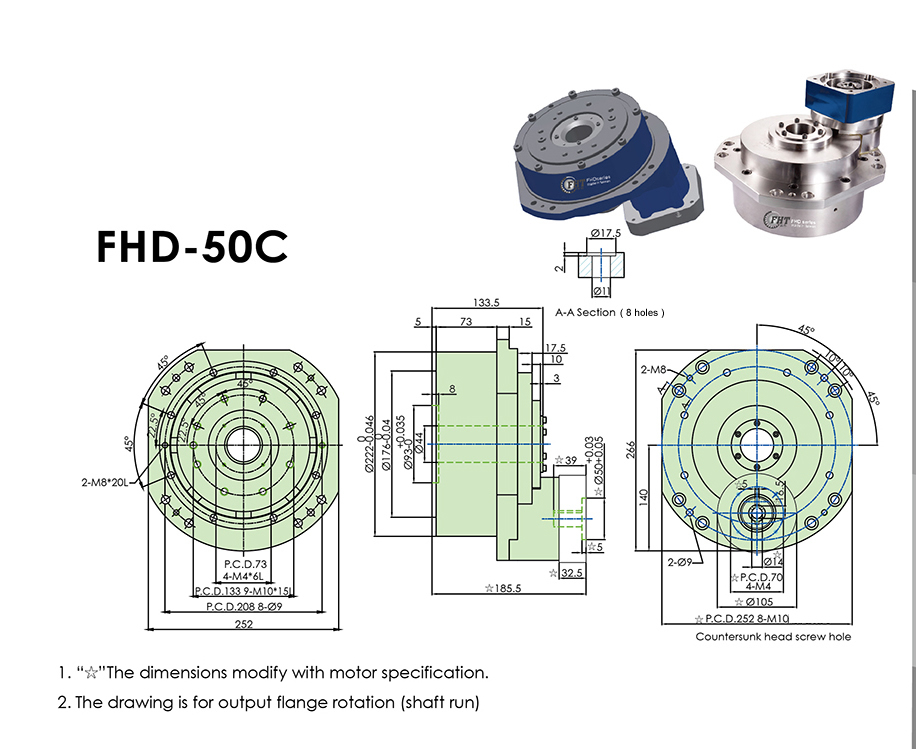

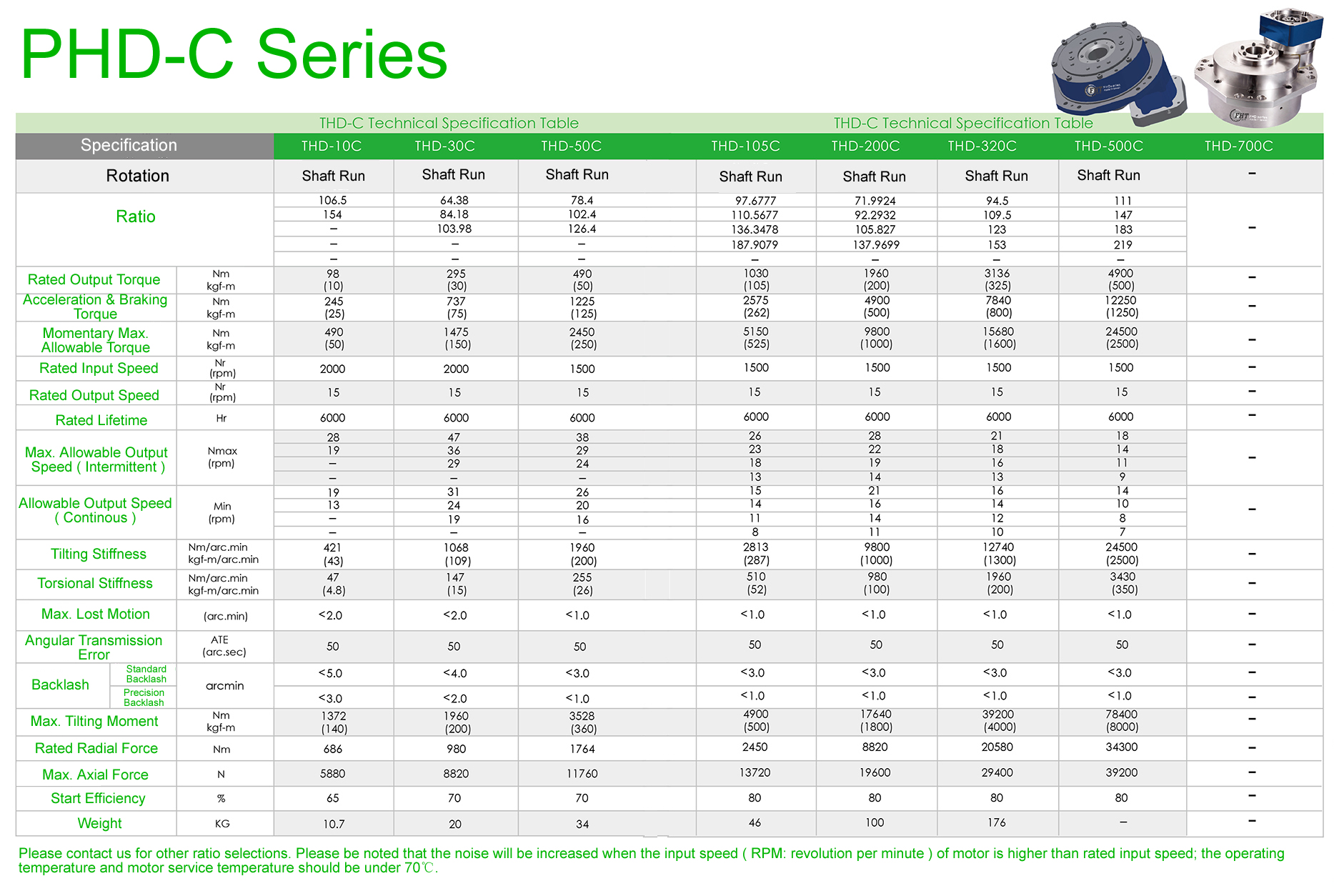

Specification Table of FHD-C Series Robot Gearbox

Catalogue of FHD-C Series Robot Gearbox

—Download the complete catalog in the top navigation bar